Ongoing Research Projects

Below you will find an overview of the current research projects at the Professorship of Circular Economy.

BioRest

Bavaria’s bioeconomy strategy aims to shift from fossil to bio-based economic practices. A collaborative project has been initiated to prepare a scientifically grounded Bavarian biomass resource strategy (Bayerische Biomasse-Ressourcenstrategie – BioReSt). The objective is to gather information on biomass flows in Bavaria and develop economically and ecologically viable approaches for their provision, utilization, and circularity. The Chair of Circular Economy focuses specifically on organic waste within this context. The methodology includes data collection, potential analysis, material flow analysis, evaluation, and strategy development.

Duration: 01/2021 – 09/2024

Project partners: Technische Universität München (Lehrstuhl Holzwissenschaft), Bayerische Landesanstalt für Landwirtschaft (LfL), Bayerische Landesanstalt für Wald und Forstwirtschaft (LWF), Technologie- und Förderzentrum im Kompetenzzentrum für Nachwachsende Rohstoffe (TFZ)

Contact person: Trond Lehmann, M.Sc.

Funded by Bayerisches Staatsministerium für Ernährung, Landwirtschaft, Forsten und Tourismus (StMELF).

Car2Car - Circular, Sustainable End-of-Life Vehicle Treatment Concepts

In order to achieve CO2 neutrality in Germany, the automotive industry is facing intensive efforts to reduce greenhouse gas emissions along the entire life cycle. One of the key levers is to increase secondary raw material quotas in vehicle and component production and thus close material cycles. The use of secondary materials in vehicle production is associated with major challenges in terms of material quality and cost-effectiveness. In addition to intelligent, automated dismantling processes, efficient preparation and sorting processes are also required to sort post-shredder products to automotive-grade quality. The economic and environmental impact must be determined along the entire process chain. The Chair of Circular Economy carries out the corresponding economic and ecological assessments of the individual processes in order to analyze the closed-loop recycling of end-of-life vehicles holistically.

Duration: 01/2023 – 12/2025

Project partners: BMW AG, TU Bergakademie Freiberg (Institut MVTAT, IEST und IGT), Helmholtz-Institut Freiberg für Ressourcentechnologie am HZDR, Technische Universität München (Lehrstuhl fml und Institut iwb), Scholz Recycling GmbH, STEINERT UniSort GmbH, thyssenkrupp Steel Europe AG, Salzgitter Mannesmann Forschung GmbH, Aurubis AG, Novelis Deutschland GmbH, OETINGER Aluminium GmbH, Pilkington Automotive Deutschland GmbH

Contact person: Dominik Reichert, M.Sc.

Funded by the Federal Ministry for Economic Affairs and Climate Action (BMWK).

FleWoKo - Flexible Living Concepts

This project focuses on the development of flexible living concepts made of wood for different phases of life (“relationship founders” and “retirees”). The housing concepts are to cover the partially identical wishes of the respective users, but are also to be developed in the sense of sustainable construction and optimised by means of various sustainability parameters (e.g. choice of materials, design of the housing concepts). In view of the oversupply of wood, the aim is to maximise the use of ZE wood (wood resulting from unplanned felling caused by random events such as windthrow or bark beetle infestation) in these housing concepts in order to put it to high-quality use and store carbon in the long term. Continuously updated information can be found on the website of C.A.R.M.E.N. e.V..

Duration: 01/2021 – 08/2024

Project partners: Gruber Holzbau GmbH, Haas Fertigbau GmbH, Holzbau Köck, C.A.R.M.E.N. e.V., HSWT – Lehrstuhl für Marketing und Management Nachwachsender Rohstoffe

Contact person: Josef Huber, M.Sc.

Funded by Bayerisches Staatsministerium für Ernährung, Landwirtschaft, Forsten und Tourismus (StMELF).

FSCM - Future Sustainable Car Materials

The necessary reduction of CO2 emissions in the automotive industry presents vehicle manufacturers and suppliers with the challenge of developing and producing sustainable vehicles and components. In addition to the increased use of secondary raw materials, this also requires new, sustainable material concepts for vehicle components. The research project pursues a holistic component and material development for plastics and metals in the exterior and interior areas. The Chair of Circular Economy supports the development of sustainable vehicle components in the interior, which are characterized by material reduction, easy dismantling, a focus on monomaterials and the use of sustainable raw materials. The individual components are evaluated and their systemic effects analyzed as part of economic and ecological assessments.

Duration: 10/2022 – 09/2025

Project partners: BMW AG, Evonik Operations GmbH, Mocom Compounds GmbH & Co. KG, WIPAG Deutschland GmbH, Thyssenkrupp Steel Europe AG, Constellium Rolled Products Singen GmbH & Co. KG, Speira GmbH, Toray Industries Europe GmbH, Technische Universität München (Lehrstuhl fml und MAT), Novelis Deutschland GmbH, material.one AG, Constellium Automotive Structures and Industry Singen GmbH, Forward Engineering GmbH, DST Dräxlmaier Systemtechnik GmbH, Fraunhofer ICT und WKI, Encory GmbH

Contact person: Dominik Reichert, M.Sc.

Funded by the Federal Ministry for Economic Affairs and Climate Action (BMWK).

FUMA - Functionally Optimized Half Masks For Infection And Contamination Protection

During the COVID-19 pandemic, demand for the disposable FFP2 mask increased dramatically. The provision of sustainable products is particularly challenging in the healthcare sector, where hygiene plays a central role. The primary goal of FUMA is to develop a sustainable, user-friendly and competitive FFP2 mask. The focus is on local value chains, high user acceptance (wearing comfort, low breathing resistance, etc.) and certification by a German testing body. Circular economy concepts whose implementation is associated with greater hurdles are also being investigated. These include concepts that rely on renewable raw materials, established and innovative recycling concepts and reuse concepts. Life cycle assessments (LCAs) are carried out during development to ensure the design of a sustainable FFP2 mask.

Duration: 04/2021 – 09/2024

Project partners: Zettl Mediatec GmbH, Sandler AG, PIA Automation Amberg GmbH, Ludwig-Maximilians-Universität München

Contact person: Svenja Klose, M.Sc.

Funded by Bayerisches Staatsministerium für Wirtschaft, Landesentwicklung und Energie (StMWi).

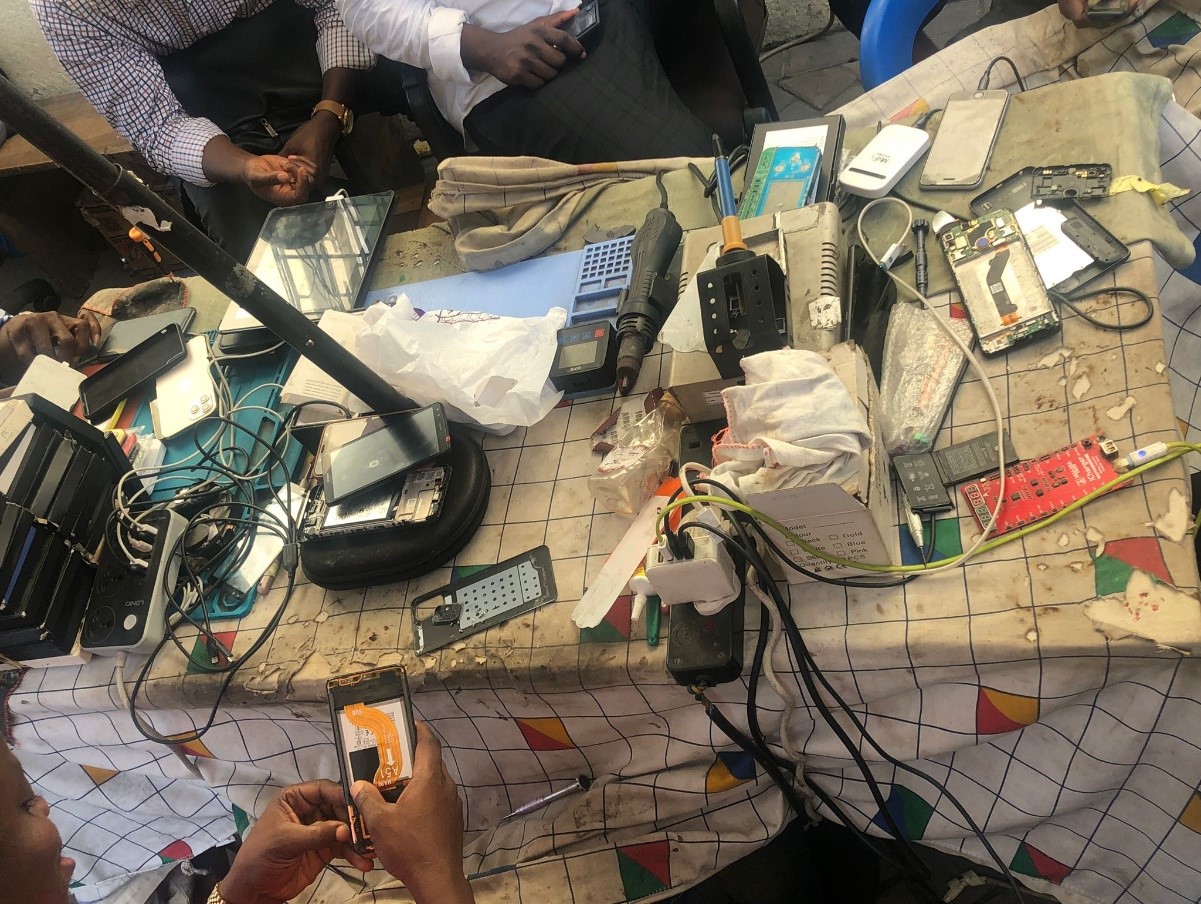

GIF KNUST 2023 - Global Incentive Fund Kwame Nkurmah University of Science & Technology

The project aims to build on the existing collaboration between TUM and KNUST by conducting bidirectional workshops. The primary objective is to build on the findings of the 2022 research trip and derived challenges and opportunities of sustainable e-waste management. The workshops will foster knowledge exchange and collaboration by bringing together central stakeholders, including researchers and students from TUM and KNUST, as well as formal and informal Ghanaian stakeholders contacted during the 2022 field trip. By fostering interdisciplinary approaches, the workshops aim to develop sustainable solutions that balance environmental concerns with the socioeconomic needs of underprivileged citizens involved in the informal recycling system. In addition, the project aims to support Ghanaian e-waste start-ups by strengthening and expanding the German-Ghanaian network to contribute to a more efficient and sustainable e-waste management ecosystem in Ghana. Expected outcomes include a deeper understanding of e-waste challenges and opportunities, interdisciplinary approaches to solving the problem, and fostering the German-Ghanaian university partnership.

Duration: 09/2023 – 08/2024

Project partners: Kwame Nkurmah University of Science & Technology (KNUST), Kumasi (Ghana)

Contact person: Vanessa Heinrich, M.Sc.

Funded by the Technical University of Munich (TUM).

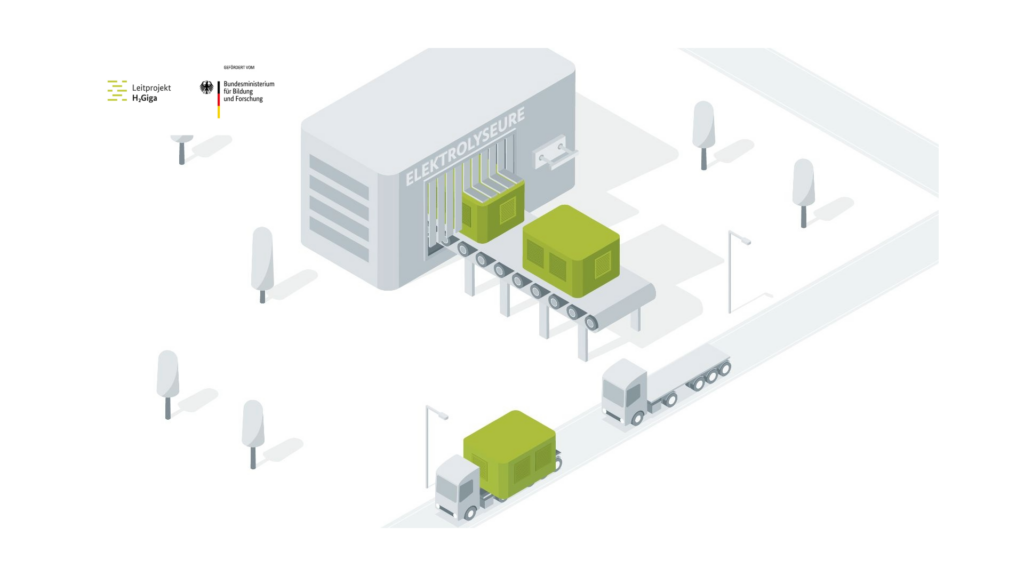

H2Giga, ReNaRe

© Projektträger Jülich on behalf of the the BMBF

Hydrogen as a universal and essential chemical raw material and energy carrier contributes significantly to cross-sectoral decarbonization as a green alternative. H2Giga, one of the three German hydrogen lead projects, is conducting research with over 30 independent cooperation projects on increasing hydrogen production through water electrolysis by upscaling and series production of the most common electrolyzer types. The ReNaRe (Recycling – Sustainable Use of Resources) sub-project is developing recycling and utilization concepts to close the material cycles at the end of the life of alkaline, proton exchange membrane and high-temperature electrolysers. The consortium of industrial partners and research institutes provides technologies and approaches that can be used in particular to close the material cycles of critical raw materials, especially technology metals, after the utilization phase of a large-scale electrolyser. In addition to the purely technical concept, the end-of-life concepts are evaluated with a life cycle assessment and techno-economic assessment. Furthermore, the development of a concept to support the circular economy of electrolyser materials through digitalization is planned.

Duration: 04/2021 – 03/2025

Project partners: TU Bergakademie Freiberg (Institut MVTAT, IKFVW), Karlsruher Institut für Technologie (Institut wbk), Fraunhofer Gesellschaft (Institut IPA), Helmholtz-Institut HZDR-HIF, RWTH Aachen (Institut IME), Heraeus Deutschland GmbH & Co. KG, Öko-Institut e.V., DECHEMA Gesellschaft für Chemische Technik und Biotechnologie e.V., Forschungszentrum Jülich GmbH, Hexis GmbH

Contact person: Sarah Hasslacher, M.Sc.

Funded by the Federal Ministry of Education and Research (BMBF).

JADS - FaCE - Facilitating the Circular Economy Through Distributed Ledger Technologies

Traditional circular economy research has focussed, to a large extent, on new materials to underpin circularity, or methods to promote efficient material flows. Important, but often overlooked, is the aspect of behavioural change. Service based models, in which goods are never owned by consumers, have the potential to transform society for the good of everyone. In this context, distributed ledger technologies (DLTs) such as blockchain have received increasing attention as a potential catalyst for the transition to sustainability. DLTs can facilitate new business models and a new era of transparency, generating economies of trust, thereby potentially transforming prevailing economic and institutional systems. The project will focus on the role DLTs can play in facilitating this transformation, especially regarding the aspects of transparency in the value cycles and new circular business models around servitisation and the sharing economy.

New research tools will be developed to analyse and assess interventions, especially policy measures and digital technologies regarding their multi-dimensional performances from a full life cycle thinking perspective. A system dynamics (SD) model will be developed to help understand how servitisation and access systems, from the micro to macro level of intervention to consumer behaviours, react to the deployment of these technologies in the shift towards circularity, and further investigate the role of DLTs in the process. A multi-scale life cycle sustainability assessment framework to assess the impacts of DLTs, transparency and servitisation will be developed and coupled to the SD model, yielding a new consequential multi-scale life cycle sustainability assessment tool that can support policy development and be used to both guiding and evaluating interventions enabled by DLTs.

Duration: 10/2022 – 09/2026

Project partners: Imperial College London

Contact person: Lyu Zhang, M.Sc.

Funded by the Technical University of Munich (TUM).

TU&M - Timberuse and Maintain

The research project is being carried out by an interdisciplinary consortium of research and industry partners. Starting with investigations at the building level, the flexibility of use and adaptability of circular timber panel construction methods will be evaluated. At the component level, component connections are examined with the aim of dismantling and separability of the component layers down to the material level. On the material level, the cascade utilization of solid wood is the focus of the qualitative and quantitative evaluations. The characterization of the utilization options of the used wood on the material level contributes to the fact that the used wood can actually be supplied to a high-quality cascade utilization after the deconstruction of the cycle-appropriate construction. A holistic view across all levels allows the integration of digital technologies for the development of a digital material passport, with the aim of documenting and tracking components, connections and deconstruction options. On the basis of life cycle analyses, the evaluation of the ecological and economic effects is carried out in addition to the technical and material-scientific assessment. The investigation of innovative economic concepts from the circular economy, such as leasing or sharing models, round off the joint project, with a look into the future of modern timber construction. More information can be found here.

Duration: 01/2023 – 12/2025

Project partners: Technische Universität München (Lehrstuhl für Holzwissenschaften, Lehrstuhl für Architektur und Holzbau, Lehrstuhl für Holzbau und Baukonstruktion, Lehrstuhl für Architekturinformatik), Haas Fertigbau GmbH, Brüninghoff Holz GmbH & Co.KG

Contact person: Josef Huber, M.Sc.

Funded by the Federal Ministry of Food and Agriculture (BMEL).