With our research works we develop tools for the analysis, assessment and design of bioeconomy and circular economy systems and apply these to problems of practical relevance. We use quantitative approaches from business administration, esp. Operations Research, and combine them with methods from engineering and natural sciences. Thus, we want to contribute substantially to the elaboration of conceptual and methodical foundations as well as specific problem solutions in the considered fields. Focus areas of our research are the topics depicted in the figure above.

SOLARSPOON develops pioneering Solar-to-Food technology by integrating photosynthetic and food-producing bacteria into self-contained devices that convert sunlight, air, and water directly into protein- and lipid-rich food materials. Cyanobacteria capture solar energy and provide electrons, which are boosted by organic dyes to power autotrophic microbes that produce nutritious biomolecules. The work focuses on improving electron transfer at the cell–electrode interface, creating microbial consortia capable of producing both proteins and lipids, and designing integrated devices that balance biological and electrochemical needs while enabling straightforward collection of food products. The ultimate aim is to demonstrate the first solar-powered system with 1% solar-to-food efficiency, opening new possibilities for sustainable food production in off-grid settings, future households, and even space missions.

Project duration

2025-11-01 – 2028-10-31

Involved Personnel

Project Executive

Sarah Haßlacher, M.Sc.

Chair of Circular Economy and Sustainability Assessment

- Doctoral Candidate

- Research Associate

- Phone:

- +49 9421 187-206

- Email:

- sarah.hasslacher@tum.de

Project Partner

Funding

EIC - HORIZON‑EIC‑2024‑PATHFINDERCHALLENGES‑01‑01 – Solar-to-X devices

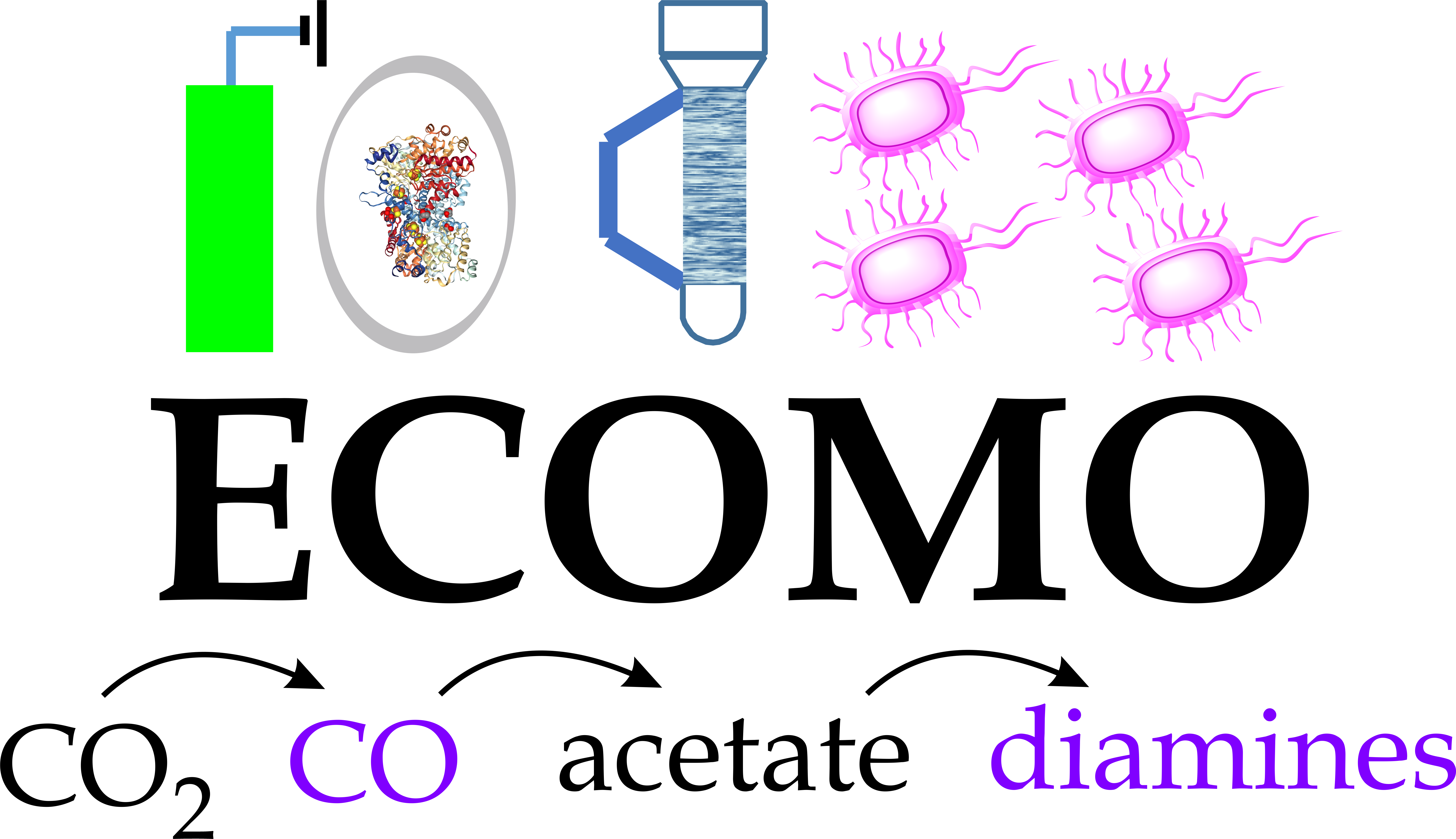

ECOMO pioneers a revolutionary approach, harnessing renewable energy, greenhouse gases like CO2 and nitrates from wastewater, to create valuable building blocks for a range of materials. Through innovative electrobiocatalytic processes and cascade fermentation, ECOMO produces high-quality diamine monomers, essential for making various polymeric materials. It combines electrochemical and biocatalytical processes in an unique way. Additionally, this porjects promotes scalability and the potential to replace unsustainable synthesis methods driven by the global need of existing and growing markets. By utilizing readily available resources like CO2 and recycled nitrates, ECOMO offers a greener alternative to traditional petrochemical processes.

Project duration

2023-11-01 – 2026-10-31

Involved Personnel

Project Executive

Sarah Haßlacher, M.Sc.

Chair of Circular Economy and Sustainability Assessment

- Doctoral Candidate

- Research Associate

- Phone:

- +49 9421 187-206

- Email:

- sarah.hasslacher@tum.de

Project Partner

Funding

EIC - HORIZON‑EIC‑2022‑PATHFINDERCHALLENGES‑01‑01 – Carbon dioxide and nitrogen management and valorisation

Traditional circular economy research has focussed, to a large extent, on new materials to underpin circularity, or methods to promote efficient material flows. Important, but often overlooked, is the aspect of behavioural change. Service based models, in which goods are never owned by consumers, have the potential to transform society for the good of everyone. In this context, distributed ledger technologies (DLTs) such as blockchain have received increasing attention as a potential catalyst for the transition to sustainability. DLTs can facilitate new business models and a new era of transparency, generating economies of trust, thereby potentially transforming prevailing economic and institutional systems. The project will focus on the role DLTs can play in facilitating this transformation, especially regarding the aspects of transparency in the value cycles and new circular business models around servitisation and the sharing economy.

New research tools will be developed to analyse and assess interventions, especially policy measures and digital technologies regarding their multi-dimensional performances from a full life cycle thinking perspective. A system dynamics (SD) model will be developed to help understand how servitisation and access systems, from the micro to macro level of intervention to consumer behaviours, react to the deployment of these technologies in the shift towards circularity, and further investigate the role of DLTs in the process. A multi-scale life cycle sustainability assessment framework to assess the impacts of DLTs, transparency and servitisation will be developed and coupled to the SD model, yielding a new consequential multi-scale life cycle sustainability assessment tool that can support policy development and be used to both guiding and evaluating interventions enabled by DLTs.

Project duration

2022-10-01 – 2026-09-30

Involved Personnel

Project Executive

Lyu Zhang, M.Sc.

Chair of Circular Economy and Sustainability Assessment

- Doctoral Candidate

- Research Associate

- Phone:

- +49 9421 187-192

- Email:

- lyu.zhang@tum.de

Project Partner

Funding

Technical University of Munich

The necessary reduction of CO2 emissions in the automotive industry presents vehicle manufacturers and suppliers with the challenge of developing and producing sustainable vehicles and components. In addition to the increased use of secondary raw materials, this also requires new, sustainable material concepts for vehicle components. The research project pursues a holistic component and material development for plastics and metals in the exterior and interior areas. The Chair of Circular Economy supports the development of sustainable vehicle components in the interior, which are characterized by material reduction, easy dismantling, a focus on monomaterials and the use of sustainable raw materials. The individual components are evaluated and their systemic effects analyzed as part of economic and ecological assessments.

Project duration

2022-10-01 – 2026-03-31

Involved Personnel

Project Executive

Dominik Reichert, M.Sc.

Chair of Circular Economy and Sustainability Assessment

- Doctoral Candidate

- Research Associate

- Phone:

- +49 9421 187-217

- Email:

- dominik.reichert@tum.de

Project Partner

Funding

Federal Ministry for Economic Affairs and Climate Action (BMWK)